Stainless Steel & High Tensile Steel Bolts & Quality Parts |

Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale Links |

|

Product Catalogues

VW Split Screen Van

VW Bay Window Van

VW Beetle

VW Type 3

VW Thing / Trekker

VW Karmann-Ghia

VW Engines T1+T4

VW Electrical

IGNITION SYSTEMS

TOOLS

Product Catalogues

Air Cooled Porsche

Rover V8 Parts

Ford Kits

BMC Era Car Parts

Land Rover Kits

|

When Building A High(er) Revving Big CC Engine With An Oil Gallery Bypass For An External Oil Filter And/Or Cooler We Have To Consider

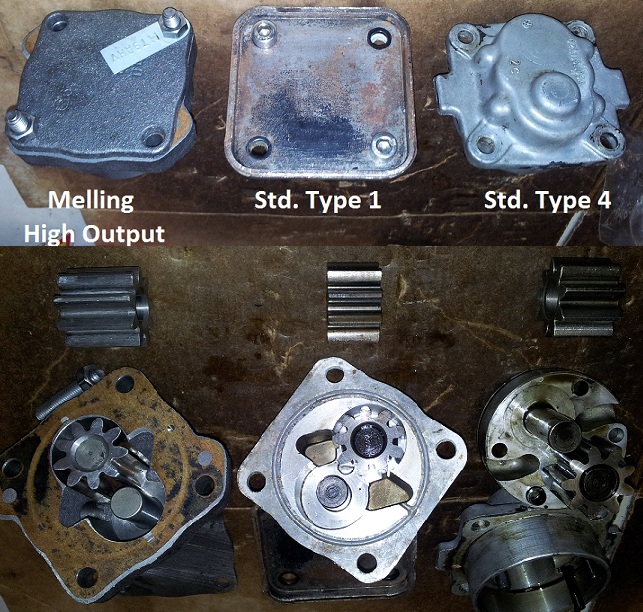

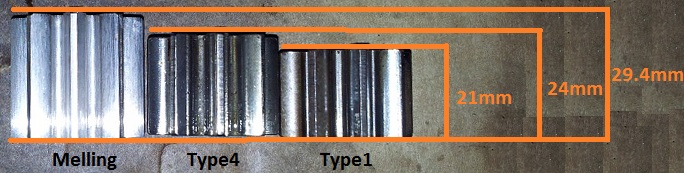

Wether The Stock Type 1 Engine Oil Pump Is Big Enough To Deliver Sufficient Oil Pressure And Volume. Luckily We Can See What VW Did For Their Own Big CC Air-Cooled Engines As They Developed 1700cc / 1800cc / 2000cc Type4 Engines. Both Type1 and Type4 Engine Fuel Pumps Can Be Seen In The Photograph Below : The Differences Are Quite Clear - The Type4 Is Of A Semi-Sealed Design With Larger Driven Gears (21mm Raised To 24mm).  The Melling High Performance Pump To The Left Is Of The Same Basic Type1 Design But With Larger Gears (29.4mm). The Pump Gear Length Measurements Are Shown Below - From Largest To Smallest  Physics And Calculations Now.! The (Lbs) Force Is The Driving Force Going Into The Pump - This Is Essentially A Constant For The Sake Of This Review - i.e. We Are Considering Using These Pumps On The Same Basic Engine. What We Can Then Derive From The Above Equation Is That As The Available Surface Area Of The Pump Increases (Cog Length As Seen In The Above Picture) Then The Pressure Delivered To The Oil System Will Increase To The Same Proportion. There Would Also Be A Proportional Increase In Oil Flow Volume. Now For The Million Dollar Question : Why Do We Need More Pressure / Flow..?

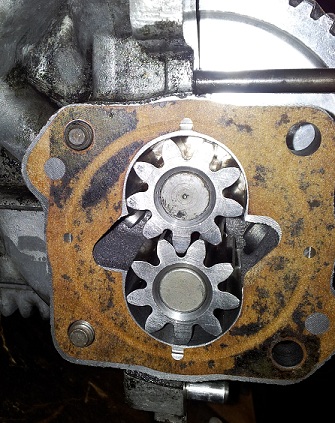

Firstly, Install The CAM And Its Gear (In Our Case An Engle 110) On It's Bearings In One Half Of The Main Engine Case, As Per The Below Picture.  The Wide Screwdriver Looking Slot In The Middle Of The CAM Is The Drive For The Oil Pump. There Is a Corresponding Key On The Back Of The Oil Pump That Engages Into This Slot Such That The Oil Pump Can Be Driven. When We Install The Oil Pump On Final Assembly We Have To Make Sure The Key Engages Into This Slot. This Has Been Accomplished In The Next Picture.  In The Above Picture We Have Installed The Melling High Performane Oil Pump Into Position To Check Its Fitment & Clearances. As Can Be Seen, This Oil Pump Necessitates The Use Of Longer Fitting Studs (+10mm Approx. Up To 60mm Length) By Rotating The CAM Shaft We Can Then Verify That The Oil Pump Gears Turn Smoothly In The Appropriate Fashion. We Can Also Verify That The Bolts Used To Secure The CAM Wheel to the CAM Shaft Do Not Fowl Or Catch On Anything As The CAM Rotates In Its Bearings. It Is Sometimes Necessary To Linish The Heads Of The Bolts Back A Little To Clearance Them.  We Also Offered The Standard VW Type4 Engines Oil Pump To Our Type1 Engine Case...  You Can Check That The Gears Are Turning By Shining A Torch Up The Oil Entry Oil Whilst You Turn The CAM Shaft...You Can Just See The Gears Inside The Semi-Sealed Casing In Our Picture. Again, The CAM Wheel Bolt Clearances Can Be Checked - With Linishing Back Of The Bolt Heads To Be Done Where Necessary. It Is Also Important To Check The Clearance Of The Four (4) Studs With Nuts On The Back Of These Oil Pumps Against The CAM Shaft Wheel And Its Bolts As These Do Protrude Slightly And May Fowl. We Have Seen These Linished Back On A Few Type4 Motors Where Eurace CAMS have been used. It Is Evidently Easier To Linish The Clearance Onto The Oil Pump Semi-Sealed Housing Bolts Where These Fowl The CAM Wheel Bolts (Within Tolerable Limits). |