Stainless Steel & High Tensile Steel Bolts & Quality Parts |

Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale Links |

|

Product Catalogues

VW Split Screen Van

VW Bay Window Van

VW Beetle

VW Type 3

VW Thing / Trekker

VW Karmann-Ghia

VW Engines T1+T4

VW Electrical

IGNITION SYSTEMS

TOOLS

Product Catalogues

Air Cooled Porsche

Rover V8 Parts

Ford Kits

BMC Era Car Parts

Land Rover Kits

The Rotating Masses In An Engine Provide An Inertial Mass (Energy Store) That Helps To Sustain Smooth Transition Across The Four-Stroke Cycle Of The Four Stroke Engine.

The Rotating Mass Helps To Dampen Out The Pulse Of The Power Stroke And The Torsionsal Twist & Harmonics Of The Crankshaft As Its Components (And Their Relative Weights) Revolves With Their Relative Out-Of-Balances.

All Of The Moving Masses Attached To The Crankshaft Assembly Add To The Rotating Mass; Flywheel, Crankshaft, Pulley Wheel and Con-Rod\Pistons.

The Larger The Out-Of-Balance (Manufacturing Tolerance) Between Components, The Larger The Rotating \ Damping Mass Has To Be To Help Dampen The Negative Effects Of These Out-Of-Balances.

Standard Production Pistons In A 2.0 Litre Type4 Engine Have Been Found To Vary By As Much As 10.0Grammes. Con-Rods By As Much As 5.0Grammes.

Production Engines Are Also Designed To Withstand Component Changes At The Clutch / Flywheel Pulley Level Etc By Workshops Without Any Thought Being Put Into Re-Balancing Things. The Mass Factor To Negate Differences On Production Engines Is Therefore Large

Conversely, Race Engines Have Con-Rods And Pistons Lightened And Balanced To Within (Typically) 0.1 Grammes And Have The Rotating Mass (Crank/Flywheel/Pulley AND Bolts) Dynamically Balanced As A Single Unit. Weight Reductions Can Be Aggresive : 2Kg Of Weight Off A Type1 Flywheel Being A Commonly Referred To Figure.

Therefore, To Release Higher Performance We Have To Balance The Rotating Parts Of An Engine And Match-Weight Opposing Componets Such As Pistons And Con-Rods Like The Racers Do. This Minimises The Out Of Balance Effects That In Part Necessitate The Large Rotatating Masses Production Engines Have To Help Negate The Out-Of-Balance Effects Of Standard Production Parts.

In Parallel To This Balancing We Can Also Implement Various Weight Reduction Measures.

Our Approaches (Below) Are A Combination Of Lightening And Match Weighting. Pictures Etc. Based On Our Development Engine 002.

- Lighten The Flywheel

- Lighten The Con-Rods

- Lighten The Pistons

1 : Lightening The Flywheel

The First Question To Ask Is "What Does The Flywheel Do?"

The Flywheel Primarily Provides A Large Frictional Surface Area For The Clutch To Work Such That Energy Can Be Transferred From The Engine To The GearBox Input Shaft Upon Actuation.

The Flywheel Also Provides A Convenient External Surface That Can Be Cog-Wheeled\Geared To Support Engine Starting Via An Electrical Starter Motor.

And As Dicussed Above, It Provides An Inertial And Damping Mass To Aid Smooth Running Of The Engine. It Is, Therefore, Very Much A 3-In-1 Peice Of Kit.!!

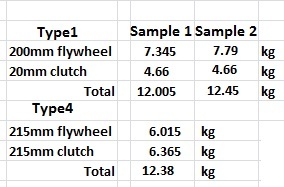

We Weighed Two 200mm Type1 Flywheels, A 200mm Clutch Pack And A 215mm Type4 Flywheel And Clutch Pack :

The Result Was Interesting In-So-Far That The Flywheel/Clutch Combination Of A 1600cc Type1 Engine Is Broadly Speaking The Same Weight As A 2000cc Type4 Engine.

On Closer Inspection You Will See That For The Type4, Some Weight Has Been Removed From The Flywheel And Transferred Into The (Bigger) Clutch Assembly Used By The 215mm Flywheel.

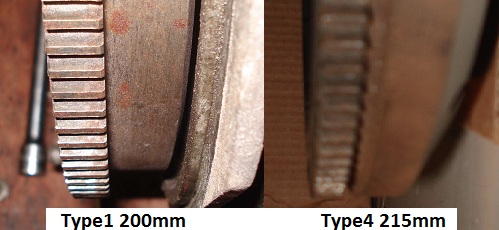

As Can Be Seen Above The Ring Of Material That The 200mm Clutch Assembly Bolts On The 200mm Type1 Flywheel Has Been Removed On The 215mm Type4 Flywheel Such That The Larger Clutch Can Be Fitted.

As Can Be Seen Above Extra Material Has Been Added To The Type4 Flywheel Behind The Gear Teeth For The Starter Motor. The Type1 200mm Flywheel Does Not Have This Material.

This Band Of Material Is Perfectly Located For Removal To Lighten The Flywheel : It Is Well Away From The Clutch Friction Faces Such That Flywheel Stiffness Or Heat Sink Zone Is Not Affected. It Is Also On The Outer Edge Of The Flywheel Where Weight Removal Has The Maximum Effect In Terms Of Moment Of Inertia Effects (Energy Storage).

Our Type 4 Flywheel With The Excess Material Removed.