Stainless Steel & High Tensile Steel Bolts & Quality Parts |

Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale Links |

|

Product Catalogues

VW Split Screen Van

VW Bay Window Van

VW Beetle

VW Type 3

VW Thing / Trekker

VW Karmann-Ghia

VW Engines T1+T4

VW Electrical

IGNITION SYSTEMS

TOOLS

Product Catalogues

Air Cooled Porsche

Rover V8 Parts

Ford Kits

BMC Era Car Parts

Land Rover Kits

|

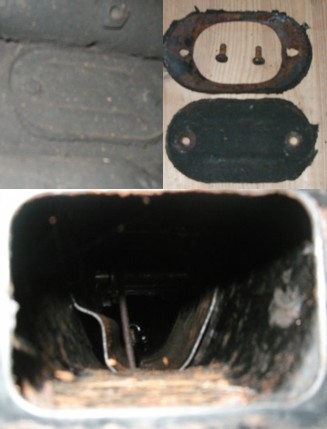

The internal cabin of our 1970 Beetle started to reek of petrol : we checked all of the fuel line conections, the twin carb connections and all looked well. We then lifted the access plate to the gear-shift coupling under the rear passenger seat to take a look inside the frame - and what we saw is as below :  The tunnel was literally flooding with petrol (under pressure from a fuel pump mounted under the bonnet) - you can see the damp patch in the bottom right of the picture.. So we inspected the hard-line connection under the rear wheel arch more closely (picture as below):  The connection to the rubber hose is itself sound - you can see the metal delivery pipe is dry around the connection. However, the bottom of the metal delivery line is damp with Petrol. Given the visisble corrosion on this pipe we presumed the pipe itself had pin-holed through with corrosion and was leaking into the frame tunnel. Corrosion and leaking of this pipe does seem (anecdotally via forums) to be becoming a common problem on old air-cooled VWs of our 1970 vintage. So we took the decision to change out this hard-line and to replace it with a contiguous length of Marine Grade Fuel Hose with a bore of 8mm (to feed our twin Dellorto 40DRLAs) We have seen this done before, including in Beetle Crisis 2 (I beleive). The first thing we did (before touching anything) was to PUMP OUT the petrol in the tank via the electric fuel pump under the bonnet. We then took a closer look at the connection under the wheel arch - gave it a 'wiggle' and ......  Good job we garaged the Beetle when we did.!! To feed the new A1 Marine Hose through we opted to leave the old hard-line in place and to feed the hose though the front frame-tunnel inspection cover plate. The cover-plate is located in-between the upper and lower members of the front-beam (as pictured below) and is held on by two M6 bolts : if the hardline itself was to be replaced then you would still need to remove the cover-plate such that access to the 90 degree bend out to the fuel tank is facilitated (as can be seen in the view up the frame tunnel in the bottom picture, as below). We have drilled our cover plate to accept a grommet through which our new fuel feed hose will pass.  The A1 Marine Hose (inner diamter 8mm) has an outer diamter of 16mm - this needs to exit the rear frame-horn at an appropriate angle such that the bending radius of the line is adhered too : without modification the original orofice would have the new hose exit as below :  Some filing of the orofice is required such that an acceptable exit angle is achieved - as per the second of the below pictures..  Next job is to start threading a guide-wire through the chassis frame tunnel such that the Marine Hose can be pulled through. We started by threading a short section of Marine Hose through from the gearbox support fork such that we could grab it through the gear-linkage access hatch. This proved the fit of the Marine Hose through this section and gave us the means of pulling our guide-wire back out through that section. In the image below you can see where we used a telescopic 'grabber' tool to pick the Hose out of the access hatch... It can be noted that we inserted an M8 bolt into the hose end to make grabbing it simpler.  To feed the guide-wire through the chassis we used an 8 foot garden cane. We lashed the guide wire to the cane and then inserted the cane up the chassis tunnel through the front inspection hatch (as previously pictured) until it reached the gearbox linkage access hatch. Using the grabber tool (as previous) we grabbed the wire from the end of the cane and then withdrew the cane. We tied the wire to the previously inserted length of Marine Hose (as per previous photograph) and then drew the Marine Hose back out through the gearbox support fork at the back - the cable is now threaded through the whole chassis from end to end.! Picture below shows the wire as it travels up and into the void of the chassis \ frame tunnel.  To feed a Marine Hose all the way through the chassis frame tunnel you will need approx 5 metres of Hosing.  Working at the front of the car \ front beam end of the car......lash the guide wire to the Marine Hose down a length of approx 40cm of the hose with lots of masking tape : tacking care to form a blunt cone point of tape in front of the hose. This can be seen in the below picture... This picture was taken after we drawn the Hose through the length of the chassis.  In the below picture we can see the achieved exit angle of the Fuel Hose as it leaves the gearbox support fork of the chassis... We pulled through sufficient length of hose to make a direct connection to the T piece to feed each Dellorto carburettor.  Our fuel pump and general organisation of piping under the bonnet can be seen below :  DON'T FORGET to use rubber grommets where the fuel hose passes into and out of the frame tunnel...these have not been shown in the photographs but are necessary to prevent chaffing of the hose. |