Stainless Steel & High Tensile Steel Bolts & Quality Parts |

Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale Links |

|

Product Catalogues

VW Split Screen Van

VW Bay Window Van

VW Beetle

VW Type 3

VW Thing / Trekker

VW Karmann-Ghia

VW Engines T1+T4

VW Electrical

IGNITION SYSTEMS

TOOLS

Product Catalogues

Air Cooled Porsche

Rover V8 Parts

Ford Kits

BMC Era Car Parts

Land Rover Kits

This article provides a review of the ignition and combustion processes such that a basic understanding of the physics of the process can be obtained. Added to this we have compiled some figures / datasheets referencing our own Type4 engine build such that we can better select products based on desirable characteristics learned from the basic understandings obtained herein.

|

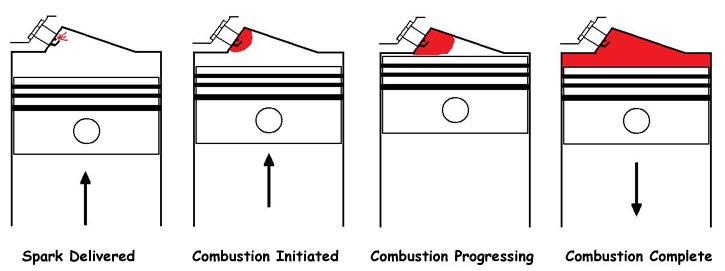

The combustion process inside an engine is a chemical reaction of hydrocarbon based fuel (Carbon and Hydrogen) and Oxygen (the active oxidising component of atmospheric air). The Hydrogen and Carbon element of the fuel burns with the Oxygen to produce Carbon-Dioxide and Water. A phenomenal amount of heat is released during this process : the heat causing the gases to pressurise and expand inside the cylinder forcing the piston down on its power-stroke to produce useful work. Combustion is initiated by a spark, with a flame front then radiating out from the spark location at a rate of between 20 and 40 m/s (Metres per Second). For most engines the combustion process takes 1mS to 2mS duration - this is a physical constant. In their literature, Bosch indicate that the point of Maximum Heat Release (and therefore maximum cylinder pressure) should occur shortly after Piston Top Dead Centre (TDC) - usually between 5 and 10 degrees After Top Dead Centre (ATDC). Some papers indicate 15 degrees is optimal : the exact point will depend very much on the design geometry of combustion chambers / cylinder heads so this will naturally vary from engine design to engine design.  The ignition combustion process can be divided into four discernable stages :

The Constant nature of the flame front propogation rate means that the timing of the spark ignition point has to be varied to compensate for engine speed such that the point of Maximum Heat Release is maintained at the optimum point. This is referred to as an Ignition Advance Curve. An interesting quoted figure is that 20% of the heat released from the burning fuel is lost to the surrounded metallic structures. Heat lost is pressure lost. Pressure lost is useful Work / Power lost from the engine. |

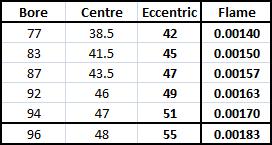

Piston Diamter V Combustion Time

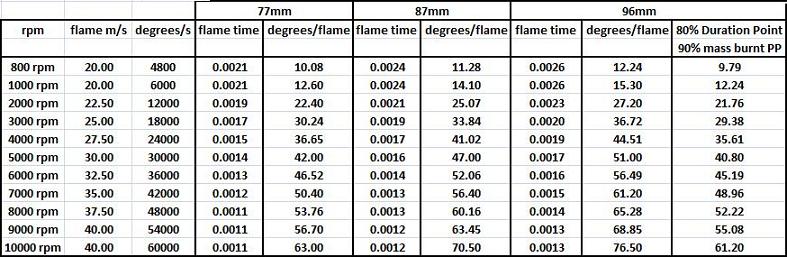

By taking a linearised mathematical approach and an average flame front time of 30m/s we can tabulate the combustion times across the more popular Volkswagen engine piston sizes as below : As the spark plugs ARE NOT centred in the exact centre of the cylinders on the Air Cooled VW we have approximated an eccentric offset - combustion is then considered fully complete when the flame front has propogated to the furthest edge of the piston / cylinder. |

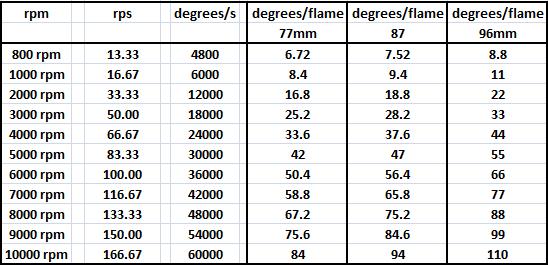

Piston Diamter V Ignition Advance (Initial)

|

By taking the above combustion time constants and applying them to pistons in motion we can get a good idea of the advance requirements for the ignitions on some popular Air-Cooled VW engines (we have included 96mm as we have these in our own Type 4 motor). All values are in reference to crank angle : so the combustion time constant is mapped against crank angle required to support it :  If we assume combustion has ended by 10 degrees ATDC then we can use these initial figures to plot the optimum advance curve V rpm for the engine. Obviously, these figures are theoretically idealised : but they can be used to get us moving in the correct direction. It can be noted that each engine CC size has its own unique advance requirement - a one size fits all approach would not be optimal This supports VWs use of a wide and varied range of Vacume Advance Cans and Mechanical Advances across the Air-Cooled VW range. (see http://www.oldvolkshome.com/ignition.htm ) VW obviously spent a lot of time and effort getting things set-up correctly for their cars / engines. It can also be noted in the generated figures that setting timing at 3.5 degrees BTDC (as per conventional VW set-up) would bring the peak pressure point inside of the 5 degrees ATDC crank angle at low rpm : we need to revise the assumptions made to generate a second set of figures closer to realism. |

Piston Diamter V Ignition Advance (Revised)

|

By revising the initial assumptions we should in theory be able to generate a more realistic set of figures for our advance curve requirements on the type4 engine (96mm pistons). Reading material released by Bosch we find : "Folding of the flame front due to turbulence and induced flows (such as swirl and tumble) are significant factors. The flows induced by induction and combustion chamber geometry (in conjunction with compression squish) fold the flame front and thus accelerate the process of energy conversion. Tumble, swirl and squish increase with engine speed: thus heat release rates increase despite flame velocity being by definition constant." So, if we take the 20m/s to 40m/s flame speed figures and assume at the bottom end of engine RPM we have 20m/s and at the top end of RPM we have 40m/s, with a progressive linear increase between the two as RPM climb then we can recalculate our figures :  The final column on the 96mm pistons table is to give as an indication of where the Peak Cylinder Pressure sits : this point being at approximatly 80% of the way through combustion total duration. If we assume a dynamic ignition setting of 3.5 degrees BTDC at 800RPM we get a position of Peak Cylinder Pressure at 6.29 degrees ATDC : this sits comfortably inside the 5 to 10 degrees indicated by Bosch in their literature. |

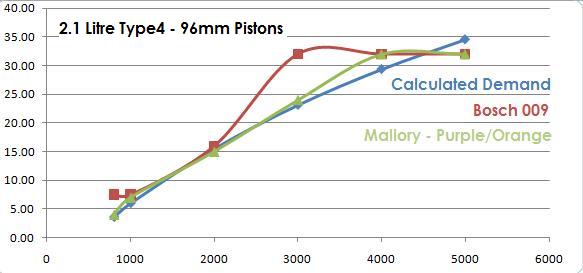

Ignition Timing Plots

By taking the above data we can quickly plot the advance required for our Type4 motor : and we can compare this to what is delivered by various distributor options : The 009 data was assembled from various datapoints harvested from the Internet. As expected - it sits about 'right' for the 1000-2000RPM range where an Industrial VW Engine Distributor would spend its life working. Either side of that it wonders off track into providing to much advance. The Mallory data points were from their own figures using the Purple and Orange Spring options : this provides a very good fit. Some fine tuning of the spring mounting tangs to provide a touch of 'right-shift' would see it all working well (in theory) The only possible way of improving on the Mallory unit would be to migrate to a full digitial electronic controller with an Ignition Map : there are also questions of drivability associated with having no vacume advance mechanism to compensate for part-throttle (sub atmospheric pressure) combustion charge mixtures / pressures. |