Aerospace, Automotive & Marine Parts |

Home About Technical & FAQ How To Buy & Contact Terms & Conditions of Sale Links |

EUROPEAN MADE HOSE BY

|

Product Catalogues

VW Split Screen Van

VW Bay Window Van

VW Beetle

VW Type 3

VW Thing / Trekker

VW Karmann-Ghia

VW Engines T1+T4

VW Electrical

IGNITION SYSTEMS

TOOLS

Product Catalogues

Air Cooled Porsche

Rover V8 Parts

Ford Kits

BMC Era Car Parts

Land Rover Kits

Fuel Composition Changes Over Time

Why Use Ethanol

Problems With Ethanol

Fuel Hose Construction

Fuel Hose Manufacturer Selection

Fuel Hose Overlapping Standards

Fuel Hose Size (Bore) Selection

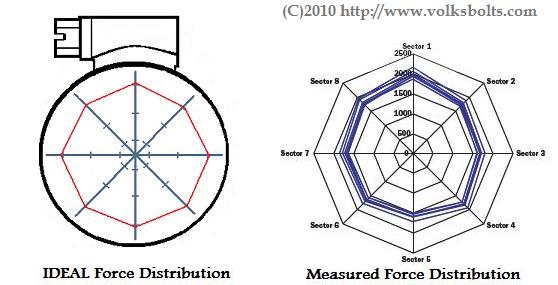

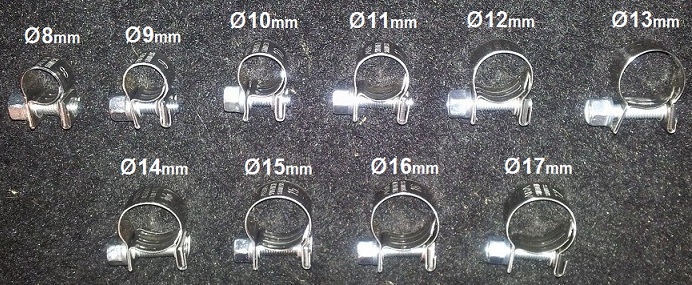

Fuel Hose Clip Selection

CHECK The Metal Inlet / Outlet Pipes On Your Fuel-Pump & Carburettor.!

|

Buy "Best In Class" SAE J30 R9 Fuel Hose Here |  |

Fuel Composition Changes Over Time

|

Petrol has changed over the years : Do you remember filling up with BS4040 Leaded Four-Star.? (4* = Approx 98 RON) We now have 95 RON (3* equivalent) un-Leaded with there being some 97/98 RON (4* equivalent) 'Super' Petrols. The majority of modern (year 2015 onwards) Petrols are blends of classical oil Industry derived Petrols and Bio-Ethanols. In the U.K. up to 5% Of Petrol is

Bio-Ethanol - As mandated by environmental Laws. This is referred to as "E5" blend (Typically 95RON). As Of Sept 2021 E5 in the UK is being phased out and replaced by E10 blend fuel (10% Ethanol) There are other additives in modern Petrols such as Oxygenators to promote cleaner burning; MTBE (Methyl-Tertiary-Butyl-Ether) being a well known additive in the USA. |

|

The molecular strucutre of Ethanol allows the fuel to burn more completely and therefore give cleaner emissions; So its use in fuel has benefits for air quality. NOx, CO, HC and particulates are reduced by up to 30% which is great for reducing SMOG. Tail-pipe emissions of CO2 decrease due to the lower Carbon-to-Hydrogen ratio of Ethanols : This makes Ethanol a great option for Governments to cut CO2 emissions nationally and hit Globally agreed targets. Ethanol has a high Octane value (109 RON) but a low Energy value. This makes it compatible with classic Petrol but means you have to burn more fuel for the same output effect from an engine. You can increase compression ratio (CR) a little to help offset the loss in MPG due to the higer Octane rating of Ethanol. The ideal Air/Fuel ratio for old fashioned 4* Petrol is 15:1 whilst with Bio-Ethanol it is 10:1 by weight - So some jetting adjustments may be needed to get the best results if you have Carburettors set up from the factory to run 4*. Modern computer controlled Fuel Injection Systems will automatically adjust based on their own sensor readings. As the majority of cars on the road today are equipped with modern fuel injection computers and are generally designed with E5/ E10 in mind then Governments

are happy to roll out E5 and E10 as there are no deleterious or unexpected side effects as such. |

|

Unfortunately, these Ethanol & Oxygenator additions to Petrol are chemically aggressive and have a tendancy to infiltrate and attack the Rubber compounds historically used to make fuel hosing, 'O' rings and accelerator pump diaphragms. These rubber components perish, swell and crack under the influence of Ethanol and ultimateley fail in their function.  Picture of perished hose end courtesy of "coopersim" on the Volkszone forum Weeping fuel lines can cause FIRES.!  There is a lot of anecdotal evidence on Internet Forums and increasing quantities of formal Technical Reports supporting this viewpoint; In both Automotive and Light Aviation user groups. In terms of selecting an appropriate fuel hose for our classic cars we need to understand where the competing Standards of commercial fuel hose come from:

As an Automotive specific standards body exists then we automatically have to make sure products conform to their standards for sale into the Automotive sector - this cover issues of liability. Though we could later cross-reference the other Standards to cross-sell into other fields such as Marine and General Aviation (MoGas Users). There is usually a high degree of overlap between Standards from these differing sectors as they do feed off each other somewhat. The specific SAE Standard for fuel conveying hoses is SAE J30, which can be broken down into its individual sub-regulations as follows; The full SAE J30 specification can be downloaded by clicking here

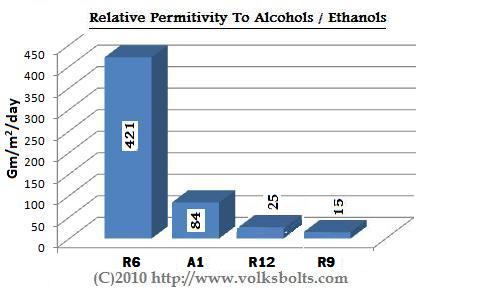

The general evolution of the hose Standard can be seen; Higher numbers representing the latest generation of Standard. Though the gradings are not entirely linear; R12 is not necessarily better than an R10 grade as the two hose standards cover different application zones. It can be seen that R9 fuel hose that has been DESIGNED to work with modern fuels has less than 3% of the permitivity of 1980s & 1990s fuel hose. It even out performs the "A1" (ISO 7840) hosing mandated for use in the MARINE environment, where they are hugely stringent about fire-safety.! (See graph below) The R6 & R12 data-points being from a reputable manufacturers data sheets; This shows that manufacturers try to EXCEED the Standard where possible.  The fuel injection grades of fuel hose (R9 & R12) are backward compatible with low-pressure carburatted cars. This and the exceptionally resistance to chemical attack, swelling and permeation of the R9 grade makes this grade ideal for use in the classic car sector. The high permitivity of older fuel hoses means that as the bio-Ethanol content of Petrol rises that the older grades of fuel hosing will rot/perish/crack/weep at an increasingly quickening rate from the point of installation. This is because the escaping vapours 'wash out' the synthetic rubber compounds that help keep the fuel hose supple - the ensuing brittleness enables cracks to develop in the hose.  Picture of perished hose end courtesy of "coopersim" on the Volkszone forum The Civil Aviation Authority (CAA) in the United Kingdom has issued a Mandatory Permit Directive (MPD) on Trelleborg "Hydro K" fuel hoses, mandating an elevated level of service checks on this type of fuel hose due to evidence of perishing in the above manner. Is it worth putting your (expensive) Camper Van at risk of catching fire for the sake of some fuel hosing..? |

|

Fuel hoses are usually constructed in layers rather than being single homogonous pieces of extruded rubber stock. The inside "fuel conveyance" layer of R9 fuel hose is FPM / FKM / Viton family rubber. A synthetic Fluoroelastomer rubber that has excellent chemical compatibility with fuels and oils including Ethanol. The only material with better compatibility is PTFE / Teflon. However, PTFE is a lot more rigid and does not lend itself to being bent into radiuses in the same way that FKM / FPM rubber does. A quick note here : "Teflon" and "Viton" are protected brand names held by DuPont of France and you are only allowed to use these brand names in sales and marketting material if you pay a license fee. This is re-inforced by their lawyers whom scoure online market places looking for infringments. Hence you will often see these materials marketted by their ISO / ASTM assigned chemical names FPM / FKM and PTFE. We use these words here for completeness of public information. Fuel hoses will also have a middle layer that contains a reinforcement layer of fibres. These range from Cotton (in Codan hose) to Aramid (in Cohline). This layering is visualised in the below graphic.  With the Codan R9 hose we see the construction goes (from inside out) FKM - NBR - CPE FKM = Fluorelastomer for Ethanol tolerance CPE is used a lot to encase electrical wires as it has good heat and chemical resistance: so it makes sense to encase fuel hosing in this material. With The Cohline DIN 73379 type 3E hose we see the construction goes FKM - ECO - ECO ECO = Epichlorohydrin Rubber ECO is a more modern version of PVC / NBR that us used extensivly to make waterproof roofing - good chemical resistance but can promote corrosion in metals so some caution is needed. |

Fuel Hose Manufacturer Selection

|

In recent years concern over quality of R9 fuel hosing has been developing in user circles; There have been suggestions that R7 hose has been re-labelled as R9.

Our experience with Codan is that fuel hose labelling can be washed so fresh labelling can be applied to custom order as they have done this for us. In our case it was removing

a leading car manufactures labels and applying a standard "Codan SAE J30 R9" scheme of labelling in its place. The independantly researched and concluding advice on the V8Register Web-Site is To buy branded fuel hose from recognised manufacturers and AVOID unbranded "generic" hosing. The downloadable slideshows on this link are well worth a read through "Branded" fuel hose will have the makers name printed down its side-wall - in addition to the specification it conforms to and it's inner diameter. For example;  This makes perfect sense in-so-far that if you have made a great product then you would be more than willing to brand your name in to it. Reputable companies such as Gates, Goodrich, Codan, Goodyear etc., all brand their original goods. (This company list is not exhaustive) Your chosen fuel hose supplier, shop or distributor should be able to provide a data sheet or a link to one on-line for your fuel hose, such as this one from Codan of Denmark - or this one from Goodyear

|

|

Buy "Best In Class" SAE J30 R9 Fuel Hose Here |  |

Fuel Hose Overlapping Standards

|

From 2014 onwards we have been aware of more "bio safe" fuel hoses, in addition to SAE J30 R9, being made available on the open market to classic car owners. Gates Barricade being one such prominently talked about hose variety; though reputably difficult to find in the U.K and non-existant in the 5.6mm I.D size desired for

air cooled Volkswagens. Looking at the datasheet we can see it is designed to meet SAE J30 R9 and R14 permitivity of 15gms/m²/day Interestingly the catalogue entry lists the Gates Barricade hosing as "Marine" but the datasheet does not explicitly state any conformance with ISO7840 Marine Hose Standards. The advice we have to give here is to only use hose clearly marked as compliant with ISO7840 if you are fitting the hose to a Marine Craft as Boat Safety Inspectors will be looking for clearly marked Marine compliance. Cohline DIN 73379 Type 3E (Rev. 11/97) is being supplied by a few companies as "bio safe" hose. We have a datasheet from Cohline here. What is becomming apparent from our research around the subject is that the SAE J30 R9 and R14 standards are becomming dominant, with competing national and industrial standards becoming subserviant to SAE for setting the de-facto for qualitative expectations. |

Fuel Hose Size (Bore) Selection

|

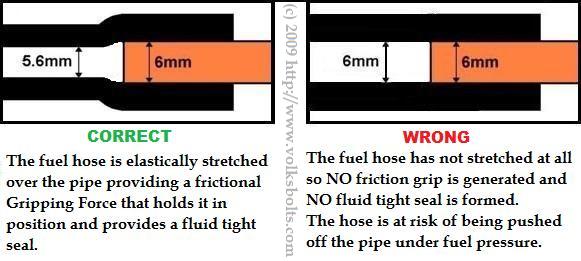

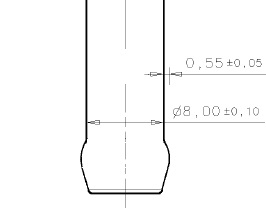

It is of EQUAL importance to select a fuel hose of the correct inner bore diameter (ID) as it is to select the correct fuel hose grading. One of the properties of Rubber materials is its elasticity; The ability to be stretched and to recoil back to its original shape. The

material essentially behaves like a spring. This is shown in the picture below - based on the stock VW application of 5.5mm/5.6mm ID fuel hosing onto the 6mm OD metal stand pipes of the fuel delivery system. The magic number for the amount a hose should stretch is 10% - confirmed in our conversations with Codan Rubber and represented in the diagrams below :-  And for Dellorto carburettor 8mm hose inlet connections :-  ALL fuel hosing connections SHOULD BE CLIPPED for extra SAFETY.....Please read on into the next section |

|

Buy "Best In Class" SAE J30 R9 Fuel Hose Here |  |

|

Buy "Best In Class" SAE J30 R9 Fuel Hose Here |  |

CHECK The Metal Inlet/Outlet Pipes On The Fuel Pump And Carburettor

|

With the increasing age and wear & tear taking its toll on Air-Cooled VW designs, people are encountering age related issues at an increased rate. One issue of specific concern is the wear & tear on the press fit metal stand pipes on the VW fuel pumps & carburettors. As can be seen in the below photograph : these press fit parts can work loose and pull out of the Aluminium castings.  Picture courtesy of Venomous Werks - Classic Volkswagen Specialist If this happens on a running engine the results could be catastrophic : regardless of whether you have used the correct fuel hose & clips. To check simply give the pipes a 'wriggle' : any looseness should be obvious. The best repair advice we have Can be summarised as below :

|

Other Useful Resources & Articles